What is Aluminum Foil?

The aluminum foil is an AL-Mn series alloy.It is a rust-proof aluminum foil with a wide range of applications, but it is not strong enough and cannot be strengthened by heat treatment. Therefore, the cold working method is adopted to improve its mechanical properties. It is necessary to have good forming performance, high corrosion resistance and good weldability for machining parts. The specific production process of aluminum foil is: melting casting-soaking-hot rolling-pre-annealing-cold rolling-intermediate annealing-cold rolling-foil rolling-slitting-performance testing-packaging. The produced aluminum foil has good formability, adhesion, and corrosion resistance. The aluminum foil produced is exported to many countries and regions around the world.

| Items | Parameters |

|---|---|

| Standard | ASTM, AISI, SUS, EN, JIS, DIN, GB ASME |

| Related grade | 1060, 1050, 1070, 1100, 3003, 3004, 5052, 5652, 5154, 5254, 5454, 5083, 5086, 5056, 5456, 2024, 2014, 6061, 6063. etc |

| Surface | Hairline ,oxidation ,mirror ,embossed ,etc |

| Thickness | 0.15m~280 mm |

| Width | 600-2800mm,or be required |

| Length | 1000-12000mm, or as required |

| Application | 1. Lighting 2, solar reflector plate 3, architectural appearance 4, interior decoration: ceiling, metope, furniture, cabinets and so on 5, plate, nameplate, bags 6, automotive interior and exterior decoration 7. Interior decoration: such as photo frame 8.household appliances, refrigerator, microwave oven, audio equipment, etc. 9. Aerospace and military aspects, such as China’s current large aircraft, the shenzhou spacecraft series, satellite, etc. 10, machinery parts processing, mold manufacturing |

Key Features of Aluminum Foil

1.The Mn element is added to make the aluminum foil have antirust performance.

2.Good moldability, adhesion and corrosion resistance, it is an excellent material for manufacturing electronic foil.

3.Non-toxic and odorless, safe and hygienic. Aluminum foil is widely used as packaging material after compound, printing and gluing.

4. Aluminum is a recyclable metal, which can be processed after being scrapped and can be put back into use.

5.It also has excellent moisture-proof performance, light-shielding and extremely high barrier ability.

Series of Aluminum

1000- series 1050, 1050A, 1060, 1085, 1145, 1070, 1100, 1350, 1200, 1235, 1060, 1A99, maily used in cosmetic caps, checker plates, cabinet sheet, lighting component stock, conductive materials, etc.

2000- series 2A12, 2024, 2014, 2017 mostly used in qunched plate, pre-streched plate.

3000- series 3003, 3004, 3005, 3104, 3105, 3A21 normally applied in battery shell, Pressure container, anodizing stock, honeycomb materials, etc.

4000- series 4004, 4104, 4343 mainly used in caldding foil sheet and plate.

5000- series 5A03, 5A05, 5052, 5052A, 5252, 5005, 5083, 5059, 5086, 5182, 5251, 5056, 5754, 5A06, 5454, 5042 Mainly applied in Anodizing materials, checker plates, elastic caps, transportation tab, automotive cover structure for new energy vehicles.

6000- series 6M63, 6M61, 6Y13, 6061, 6063, 6A02, 6082, 6016, 605A, 6101 Used in qunched plate, composite board, car doors, etc.

7000- series 7072,7075 used in Qunched plate, pre- stretched plate, etc.

8000- series 8011, 8021, 8079, 8006 applied in Beverage foil, cable foil, pharmaceutical foil, blister foil, etc.

Applications of Aluminum Foil

As people’s demand for electronic products becomes more and more extensive, which promotes the rapid growth of the electronic information industry, emerging electronic products are emerging endlessly, so the demand for aluminum electrolytic capacitors is also increasing. The production bases of aluminum electrolytic capacitors in many countries are transferring to China, which promotes the rapid development of electronic foil processing industry in China. Therefore, as the raw material of electronic foil, aluminum foil will have a good market prospect. Due to the good formability of aluminum foil, it is also widely used in aviation meal boxes.. It can also be used as an aluminum honeycomb core.

Top 3 Aluminum foil manufacturer

1. Aluminum Corporation of China Limited (“Chalco”)

Chalco was incorporated on September 10th, 2001 in China, Chalco is its controlling shareholder. Chalco is a leading company in China’s non-ferrous industry, with a strong portfolio of assets among global competitors. It is also the only large company in China’s aluminum industry that’s engaged in the whole value chain, from exploration and mining of bauxite and coal, the production, sales, and R&D of alumina, primary aluminum and aluminum alloy products, to international trade, logistics, and power generation from both fossil fuels and new energy. Currently Chalco has 39 subsidiaries, 18 wholly owned and 21 controlled ones. Chalco has been listed in the New York Stock Exchange (stock code: ACH), the Stock Exchange of Hong Kong (stock code: 2600), and Shanghai Stock Exchange (stock code: 601600).

2. Aluminum corporation of America (“Alcoa”)

Alcoa Corporation (a portmanteau of Aluminum Company of America) is an American industrial corporation. It is the world’s eighth largest producer of aluminum, with corporate headquarters in Pittsburgh, Pennsylvania. Alcoa conducts operations in 10 countries. Alcoa is a major producer of primary aluminum, fabricated aluminum, and alumina combined, through its active and growing participation in all major aspects of the industry: technology, mining, refining, smelting, fabricating, and recycling.

3. Emirates Global Aluminium (“EGA”)

Emirates Global Aluminium is the world’s largest ‘premium aluminium’ producer and the biggest industrial company in the United Arab Emirates outside oil and gas. Emirates Global Aluminium’s product range includes more than 330 individual primary aluminium products that are made to customer specifications, and most of our aluminium is allocated to customers a year in advance.

Transport of Aluminum foil

For aluminum plates and coils, packaged in apecial papers and wooden support firsly, then loaded into the containers with the fasten measures.

20 FT Internal (L x W x H) 6010mm x 2340mm x 2390mm

40 FT Internal (L x W x H) 12110mm x 2340mm x 2390mm

40 HC Internal (L x W x H) 12110mm x 2340mm x 2690mm

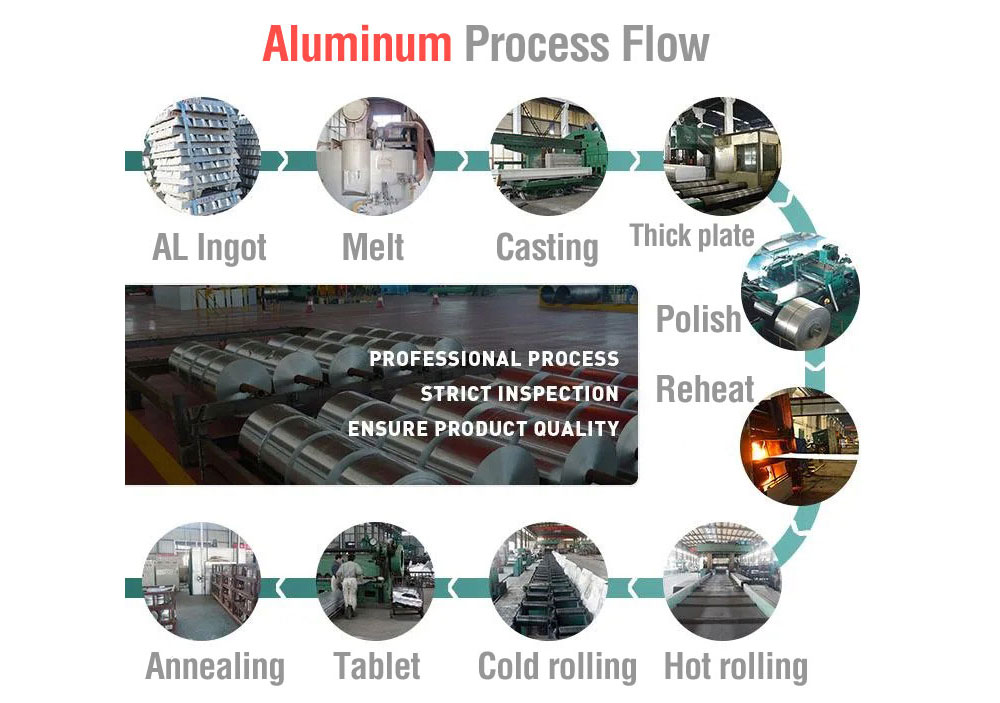

Aluminum Foil Manufacturing processing

The whole aluminum production line start from the aluminum ingots, the aluminum block will be taken to the casting machine after melting in the melting equipment. After shaping the block to the thick plates, polishing in the special device, the aluminum thick plates are reheated in the furnace.

After hot rolling, cold rolling, the thick aluminum sheets will be tabletted into the smaller and thin pieces, the final procuts will be packed after the annealing.